How to arrange your work site

In order to be able to work in a safe and secure manner you need to arrange your various work sites for the task you have been assigned to do.

Below is a list of areas to which you must pay special attention:

-

Transport lanes

The transport lanes in the warehouse must be level, stable, non-skid, free of holes and rough spots and must be well illuminated. This also applies to outdoor transport lanes which in addition must be easy to clear of ice and snow and unable to form pools.

-

Ramps and other sloping surfaces

Ramps and other sloping surfaces may be problematic if you need to transport heavy pallets on them. When moving heavy pallets on a pallet lifter, the maximum allowed gradient is 1:50 which is equal to 2 cm per linear metre. If the ramp is shorter than the distance between front wheel and rear wheel of the pallet lifter, meaning that one wheel is resting on a horizontal surface, the maximum ramp gradient is 1:20 which is equal to 5 cm per linear metre.

-

Width of pathway

The width of the pathway depends on the load to be transported and whether you are using any technical aids. Basically, the free space should be 30 – 50 cm on either side of the load. When passing through doors and gates, the free space between the load and door frame/sides of the gate should be approx. 20 cm.

-

You need plenty of space

You need plenty of space in order to be able to work freely and without hindrance when pushing, pulling and lifting. A person needs approx. 1 x 1 metre free space to allow body and feet to work in a natural pattern of movement. You must also allow sufficient space for the load to be moved as well as for the technical aid.

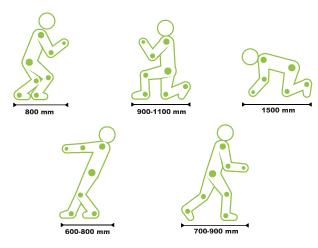

The illustrations show how much space your body takes up in various work situations:

Source: EN/ISO 14738

-

Draught and high or low temperatures

Draught and high or low temperatures must not constitute a nuisance in the room where you work most of the time.

-

Wheeled traffic and foot traffic

Wheeled traffic and foot traffic are not necessarily separated in warehouses for which reason internal traffic rules must be drawn up. The same applies to areas in which loads at heights exceeding two metres are handled. Permanent work sites as well as pathways must be secured against falling objects from e.g. stacked pallets or from racks.

-

Lighting

The lighting must be adjusted and placed in such a way that the lighting fittings do not emit any annoying reflections or glares in areas of work or transport.

Danish Standards DS 700 provides guidelines for the minimum amount of lighting with the artificial illuminance stated in lux. Typically, the lighting requirement for transport lanes and on ramps is 50 lux.

In working areas where texts must be read or precision work is performed the requirement is between 200 and 500 lux. In the event of special requirements as to colour and quality control the colour rendering of the lighting equipment should be adapted (choice of Philips code). In addition, there should be access to daylight and view to the open.